Request for Quotation

Product Short Descriptions

Per Standard Bag = 25KG

Per Standard Pallet = 60 BAG

Terms and Conditions:

1. The principle of “while stocks last” will be applied.

2. All purchases made are non-refundable.

3. Orders weighing below 1,000kgs are strictly for own collection from the seller’s warehouse.

4. Free delivery is exclusively offered within West Malaysia for orders meeting the MOQ.

5. Additional charges may be applicable for Kelantan, Terengganu, and Pahang.

Description

SCGC™ PP P400S is a homopolymer polypropylene resin which is specially designed for flat yarn or raffia products and monofilament application as well. P400S offers good features for Flat Yarn application as consistency process ability, high productivity with balance good mechanical properties.

Shipping

Shipping States: Perlis (Malaysia), Penang (Pulau Pinang) (Malaysia), Perak (Malaysia), Kedah (Malaysia), Malacca (Melaka) (Malaysia), Negeri Sembilan (Malaysia), Johor (Malaysia), Kuala Lumpur (Malaysia), Putrajaya (Malaysia), Selangor (Malaysia), Terengganu (Malaysia), Pahang (Malaysia), Kelantan (Malaysia)

Additional information

| Weight | 25 kg |

|---|---|

| Typical Application | Raffia, Flat Yarns, Woven Bags, Flexible Intermediate Bulk Containers, Ropes & twiners, Sheet, Stap, Straw |

| Product Characteristics | Good process ability, High productivity, Good mechanical properties, Food contact applicable |

| Melt Flow Rate (230°C, 2.16kg) | 3.5 g/10min (ASTM D1238) |

| Density | 0.91 g/cm³ (ASTM D1505) |

| Melting Point | 163°C (ASTM D2117) |

| Vicat Softening point (1kgf) | 155°C (ASTM D1525) |

| Heat Deflection Temperature (4.6kg/cm²) | 110°C (ASTM D648) |

| Tensile Strength at Yield | 350 kg/cm² (ASTM D638) |

| Tensile Strength at Break | 230 kg/cm² (ASTM D638) |

| Elongation at Break | 650% (ASTM D638) |

| Flexural Modulus | 15500 kg/cm² (ASTM D790) |

| Notched Izod Impact Strength (23°C) | 40 J/cm (ASTM D256) |

| Haze | 50% (ASTM D1003) |

| Gloss | 65% (ASTM D2457) |

| Notes | Conversion factor for changing unit from kg/cm² to MPa is divided by 10.20. |

| Recommended Processing Conditions (Flat Yarn) | Processing temperature around 190°C – 260°C, Strectching Temperature 140°C – 160°C, Stretching Ratio 5 – 7 |

| Recommended Processing Conditions (Monofilament) | Processing temperature around 250°C – 280°C, Stretching Temperature 95°C – 105°C, Stretching Ratio 8 – 12 |

| Remarks | These conditions are only guidance for actual processing conditions should be adjusted case bycase because it depends on machine type, screw configuration, product design and environment |

| Storage | Product(s) should be stored in dry and dust free location at temperature below 50°C and protected from direct sunlight and/or heat, well-ventilated area, away from incompatible materials and food and drink, as this may lead to quality deterioration, which results in odour generation and colour changes and can have negative effects on the physical properties of this product |

Discussion (0)

Share your thoughts!

Let us know what you think...

Only logged in customers who have purchased this product may leave a review. Log in now

Vendor Info

Vendor Information

- Store Name: Toling Corporation (M) Sdn. Bhd.

- Vendor: Toling Corporation (M) Sdn. Bhd.

- No ratings found yet!

More Products

-

Lotte LDPE LDF265YZ TITANLENE

Request for QuotationMin (55 units)RFQ -

Lotte PP SM128 COPO TITANPRO

Request for QuotationMin (50 units)RFQ -

Lotte HDPE HB0972 TITANEX

Request for QuotationMin (50 units)RFQ -

Lotte LDPE LDF200YZ TITANLENE

Login to view price RFQ -

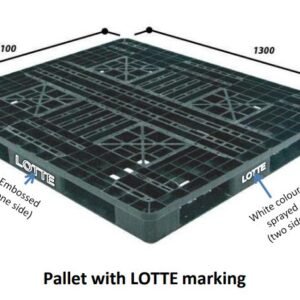

LOTTE PLASTIC PALLET (NOT FOR SALES)

RM38.00 -

Lotte PP SM798N COPO TITANPRO

Request for QuotationMin (50 units)RFQ

Product Knowledge

Details

- Plastic Number:

- 5

- Raw Material:

- Vietnam

What others are saying

There are no contributions yet.